High Retention Media

Azurtex™ 2.0 and Primapor™ Filter Media

Our high retention, chemically treated textile products are the result of an extensive research and development program to determine the most efficient medium for the separation of extremely fine particles in aqueous dispersions. Clear Edge has widespread patent and trademark coverage for this technology.

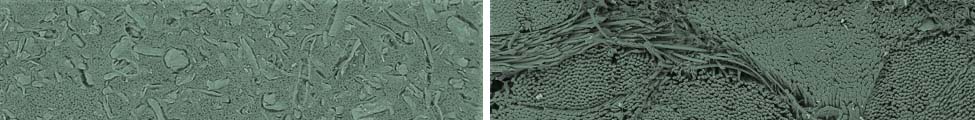

Azurtex™ 2.0 and Primapor incorporate a base substrate with a modified cell-like structure that forms closely intertwined channels that virtually exclude the passage of even very small particles. This means that the filtration efficiency is excellent and a clear filtrate is produced. In many cases, product retention close to 100% can be achieved.

Why Choose Azurtex™ 2.0 and Primapor™ ?

- Surface filtration

- Excellent particle retention

- Superior cake release

- Reduced blinding tendency

- High flow rates

- Longer fabric life

Azurtex™ 2.0 and Primapor™ Value Proposition

High Retention Efficiency

- The microporous chemical application of Azurtex™ 2.0 and Primapor™ penetrates and fills the pores of the fabric, thereby restricting separated particles to the surface of the media, which virtually eliminates blinding whilst increasing product retention.

Clear Filtrate

- The tortuous structure of Azurtex™ 2.0 and Primapor™ ensures superior clarity of filtrate over conventional media, minimizing, if not obviating, the need, where applicable, for filtrate recycling.

High Throughput

- By virtue of the special chemical formulation and application, even higher filtrate throughput is possible. The tendency for conventional filter fabrics is to blind or block over time. These unique products prevent this, enabling higher flow rates for longer, meaning production times are reduced, significantly improving Total Cost of Ownership (TCO).

Excellent Cake Discharge

- Improved cake release means shorter cycle times, less time for cleaning and improved production efficiency. Product yield is also increased.

Drier Cakes

- Azurtex™ 2.0 and Primapor™ produce drier cakes. Excellent retention efficiency, high throughput, and resistance to blinding all help reduce the cake moisture. As a result, savings in drying costs are achieved.

Extended Service Life

- Improved service life over traditional woven products with its anti-blinding properties, whilst eliminating the possibility of surface damage through resource draining manual scraping.

Azurtex™ 2.0

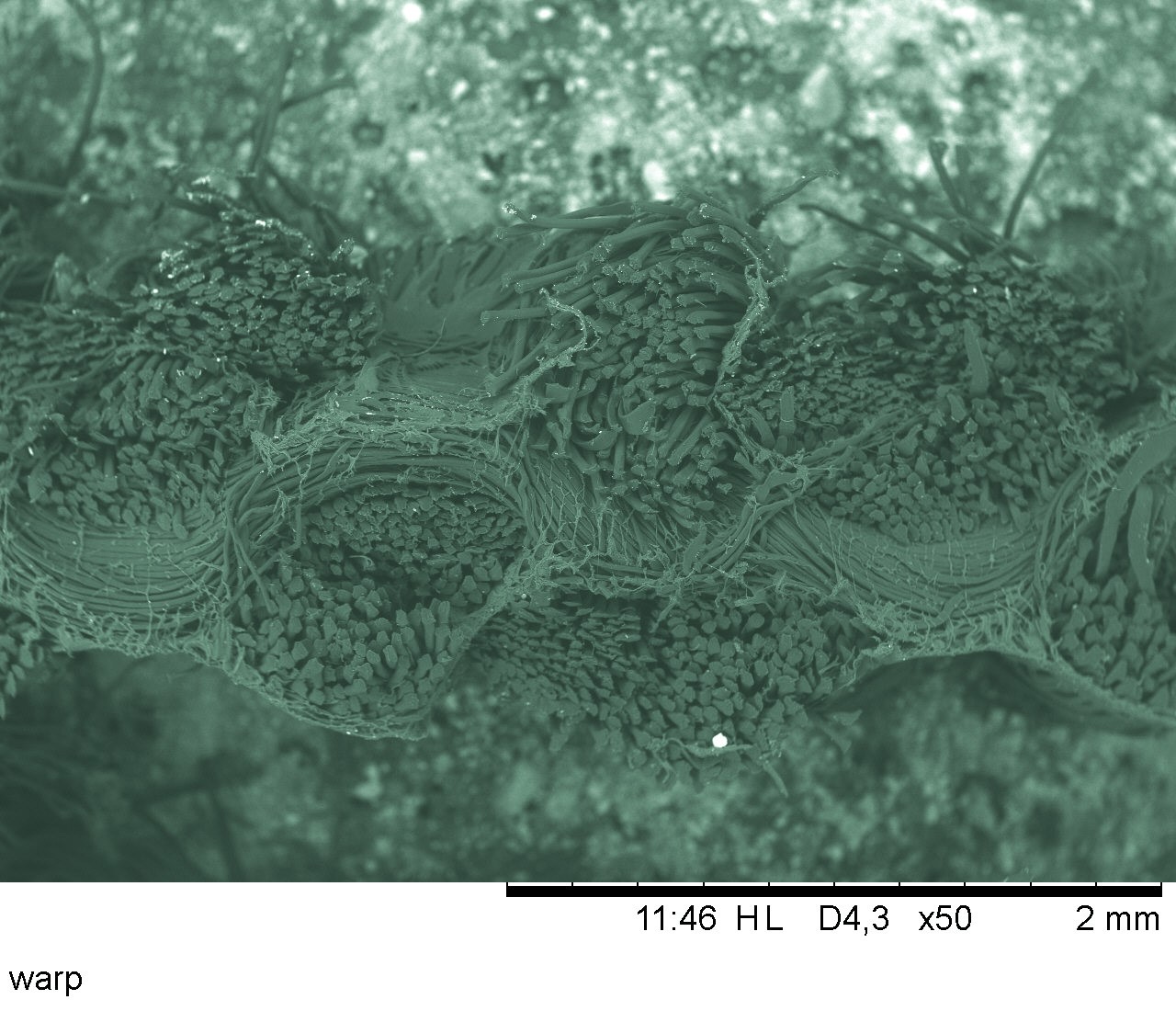

Azurtex™ 2.0 is manufactured using a proprietary impregnation technique, specifically designed to confine the chemical treatment to the inside of the woven structure of the substrate. Particles collected during filtration are distributed entirely on the surface. This means that the chances of blinding are significantly reduced, a problem experienced when using more traditional cloths. Azurtex™ 2.0 is ideally suited to pressure filtration equipment applications (E.g. Horizontal Chamber Press).

Download the Clear Edge Azurtex™ 2.0 brochure

Primapor™

Primapor™ is manufactured using a proprietary chemical coating technique, which creates a robust ‘skin’ like surface on top of the substrate. As with Azurtex™ 2.0, particles collected during filtration are distributed entirely on the surface, again reducing the chances of blinding. Primapor™ is ideally suited to vacuum filtration equipment applications (E.g. Moore Vacuum Leaf Filters).

Target Markets / Applications

Azurtex™ 2.0 and Primapor™ are there to enhance, optimize and maximize the Total Cost of Ownership (TCO) potential in these chosen markets.

- Fine Chemicals

- Minerals

- Mining

Azurtex™ 2.0 and Primapor™ consist of a variety of constructions, weights and permeabilities that are designed to cover the most demanding fine particle/high retention applications

- Titanium dioxide

- Kaolin (China clay)

- Dyes and pigments

- Ceramics

- Ferric oxide

- Metal carbonates

- Calcium chloride

- Zeolite

- Gold refining

Request a quote or contact Clear Edge for custom Azurtex 2.0 filter cloths, tailored to your industrial needs.

Coated media selection by equipment type

| Filter Equipment | Azurtex™ 2.0 PP | Azurtex™ 2.0 PET | Primapor™ |

| Belts | ✔️ | ||

| Candle Filters | ✔️ | ||

| Chamber Filter Press | ✔️ | ||

| Pressure Leaf Filters | ✔️ | ✔️ | |

| Rotary Vacuum Disc Filters | ✔️ | ✔️ | |

| Rotary Vacuum Drums | ✔️ | ✔️ | |

| Vacuum Leaf Filters | ✔️ | ✔️ |