2025 Filtration Industry Trends: What’s Next for Mining and Chemical Industries

Introduction

As we have now entered in 2025, the filtration industry is gearing up for game-changing advancements that promise to transform the processes and workflows of the mining and chemical industries. From advancements in polymer and yarn technology to embracing AI-driven filtration solutions, the industry is adopting smarter, more sustainable, and more efficient systems.

The filtration industry is realizing and acknowledging the growing significance of smart filtration in increasing productivity and efficiency, especially in the mining and chemical industries. Apart from that, the transformative filtration trends of today also contribute to making the operational processes safer and healthier, significantly reducing bio-hazards.

The recent developments in process filtration technologies, filter media materials, and designs have led to more efficient, reliable, and longer-lasting filter equipment. To showcase these latest technological advancements, industry experts, professionals, and researchers have come together in FILTECH, held in November 2024 in Cologne, Germany. As the most well-known global event in the filtration industry, it provides an opportunity to explore targeted solutions for filtration challenges and boost excellence.

Let’s look at some of the emerging trends in industrial process filtration for the mining and chemical industries.

Mining and Chemical Industry Outlook for 2025

Trends in Industrial Process Filtration for Mining and Chemical Industries

An increasing focus on enhancing the bottom line while practicing sustainability is reshaping the process filtration landscape and driving operational efficiency, workflows, and processes. Here are the major trends reshaping filtration:

Innovation in materials used – Contaminants are often responsible for machine breakdowns, resulting in production downtime that affects costs and efficiency. The filtration industry has made significant progress in addressing these issues by adopting the following:

- Longer-lasting filter fabric designs

- High-performing filter cloth

- Automated filter monitoring

So, before initiating the filtration process, some essential factors, such as particle size, flow rate, and chemical compatibility, must be carefully considered while selecting the filter cloth.

Sustainability – Organizations worldwide across various sectors are adapting to environmental, social, and governance [ESG] as governments in different countries are implementing stringent regulations to reduce carbon dioxide emissions and footprint. For example, the UK government has set a statutory guideline to reduce emissions by 81% by 2035. So, to meet such guidelines from different countries globally, the filtration industry is coming up with high-performing filter media and advanced filter fabric.

Tailings process – The tailing process in filtering is crucial for managing waste effectively. As an effort toward environmental protection, each country outlines its tailing standards along with mining regulations to reduce the hazardous nature of mining activities.

Increased use of AI-driven technology – AI-driven technology has a transformative impact on process filtration for the mining and chemical industries. In these sectors, understanding and predicting the environmental conditions can impact the filtration efficiency and output. For example, places with extreme temperature changes and high or low humidity can cause damage to the filter cloth.

Thus, along with the advancements in filtration technologies and the advent of smart filtration solutions, the most essential element in removing impurities is the efficiency of process filtration.

Significance of Process Filtration

As we know, “process filtration” in the mining and chemical sectors is crucial for purifying raw materials and final products at various stages of production. The different process stages include:

Feed Preparation – At this stage, the raw material gets prepared by checking the consistency and adjusting or adding necessary chemicals.

Filtration Stage – As the most important stage, the raw material prepared is passed through a filter cloth, where the liquid and the solid get completely separated with 100% efficiency. In some industries, the solid could be the main product, and the liquid is the impurity, while in some other sectors, it is the opposite.

Cake Washing [As per requirement] – If required, then at this stage of the process, the filter cake is washed further to remove any residue impurities.

Consequently, you need to work closely with an efficient filter fabric manufacturer who is aware of the requirements and the challenges faced by the mining and chemical industries. Additionally, the experts you partner with should also be well-versed in the regional and international standards of regulatory compliance of the industry.

Challenges of Filtration in the Mining and Chemical Industries

As regulations tighten in the mining and chemical industries and the operational demands increase, the filtration industry finds itself at a crossroads of innovation and necessity. Here are some of the factors that are likely to shape filtration in mining and chemical sectors:

Price fluctuation of raw materials – The price of raw materials significantly affects operational costs, especially for inputs such as fuel, material, labor, and equipment. Increased fuel prices impact transportation costs of raw materials, impacting the companies’ margins.

Sometimes, mines focus on reviving the ancillary metals if the price of that metal is high. However, this whole process of reviving doesn’t prove to be cost-effective if the cost of the revived metal is low. Such an example could be the separation of Zinc from a zinc-copper alloy, or Aluminum is a byproduct of alumina produced from bauxite.

Environmental impact – Some factors might raise environmental concerns. Consequently, researchers in the filtration industry are working on using recyclable materials to develop filter cloth to minimize the impact and reduce pollution and carbon footprint.

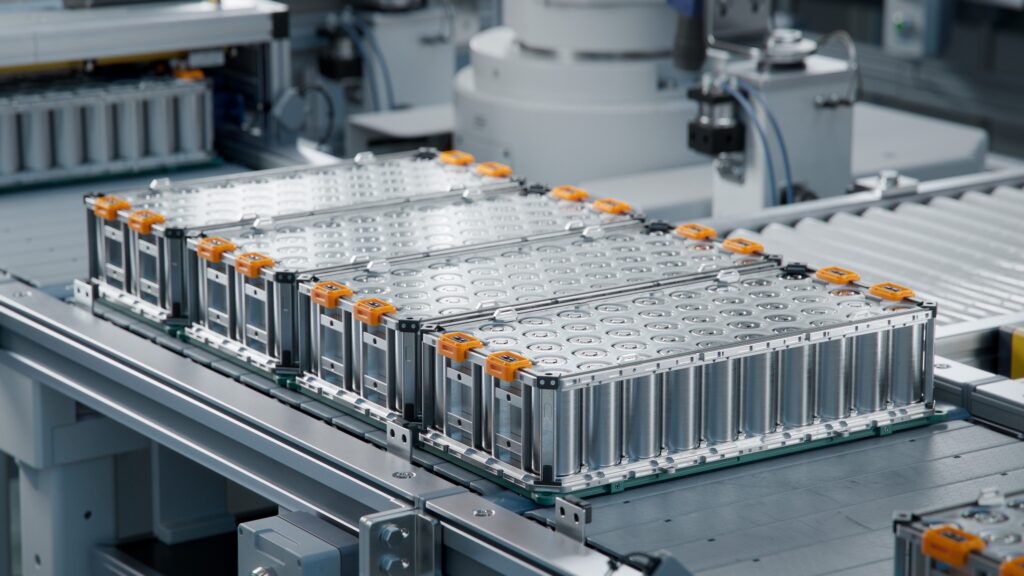

Additionally, a Canadian battery components company has developed a process for producing lithium metal from lithium carbonate, reducing the number of steps and harmful byproducts in the lithium washing process.

Economic factors affecting chemical production – Multiple factors influence chemical production, such as raw material costs, energy prices, government regulations, currency fluctuations, transportation costs, global economic conditions, and environmental compliance costs.

Clear Edge Advantage in Embracing the Next Chapter in Mining and Chemical

Despite multiple challenges affecting filtration in the mining and chemical industries, Clear Edge is all set to overcome these challenges upfront with game-changing advancements in process filtration. Our smart filtration solutions reduce the Total Cost of Ownership (TCO) by increasing efficiency and productivity, delivering long-term savings and superior performance.

Want to know your TCO? Get it calculated by our filtration experts. Feel free to reach out to us Here.

We continue to invest in innovation by developing materials, tools, and equipment to simulate complex objects in our lab [equipped with CFD] and scale the technology to suit specific customer programs.

Some of the features that set us apart from our competition include the following:

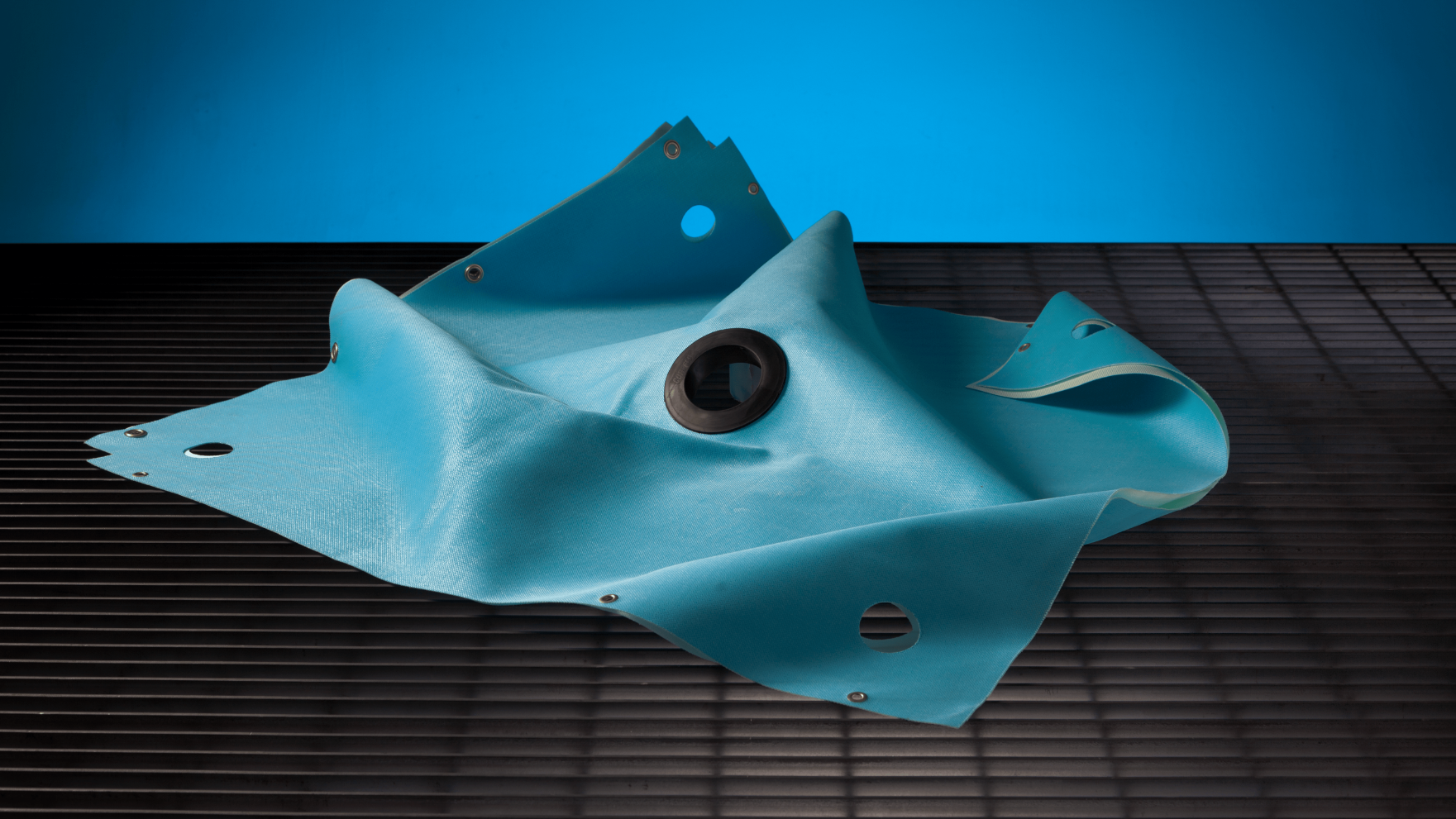

Filter fabric/ cloth – Empowered by Material Science by Clear Edge, we constantly develop innovative filter media to ensure we stay at the forefront of filtration technology. We believe that material science is crucial for unlocking international standards of innovative filtration solutions.

Smart filtration – Equipped with expertise and a solution-driven approach, we provide our clients with on-site testing possibilities at their facility. It enables our expert team to address their challenges faster and deliver expedited resolution by leveraging our advanced filtration process solutions.

Energy efficiency – An energy-efficient filtration system is essential for the chemical and mining industries due to the energy-intensive nature of its processes. Our hybrid filtration technologies, combining traditional methods and emerging technologies, deliver higher efficiency with reduced energy consumption.

Wide network and reach – Our wide network and global reach across 165 locations in 27 countries enable us to provide our clients with fast turnaround time in the industry. Committed to global environmental awareness, we work closely with our clients as their trusted partners, empowering them to meet regulatory requirements and contribute to a more sustainable future.

Our widespread network helps us follow a “Process Anywhere” approach that empowers us to support and deliver our customers worldwide with a faster turnaround.

Trusted partner – We are the trusted partners of our customers across all the major countries, which establishes us as one of the global leaders in supplying industrial filtration products and filter media to customer applications worldwide. We have over 200 years of filtration legacy, adapting filter media for various applications such as separating liquids and solids, dewatering, collecting and filtering dust, air filtration, filtering and purifying hot gases, and other industrial processes.

Customer Care – At Clear Edge, we care for our customers. We are committed to delivering innovative solutions that benefit our customers and contribute to a more sustainable future. While helping your business achieve its full potential by minimizing downtime and maximizing production, we ensure that the operational processes are safer, healthier, and more productive.

Conclusion

The filtration industry is well-positioned to address both efficiency and sustainability challenges in the mining and chemical sectors. As we approach 2025, advancements in smart technologies, energy-efficient models, and innovative industrial filtration media will continue to drive progress. These trends are vital for staying competitive in a world where resources are increasingly scarce.

Filtration systems are proving indispensable, whether in recovering critical metals essential for a green economy or ensuring compliance with stringent regulations. It’s clear that the mining and chemical industries have a promising future, where enhanced filtration technologies will deliver better results for businesses, people, and the planet.

Need assistance finding the perfect industrial filter fabric? Contact us today to discuss your requirements—we’re here to help you find the ideal solution!

Let your network know; share this blog on LinkedIn!

Are you commissioning a lithium plant and seeking insights into the critical role of filtration in lithium production? Clear Edge is your trusted partner. Our filter cloths are designed to meet the unique demands of the lithium mining industry, ensuring optimal performance and sustainability. Discover how we’ve collaborated with industry leaders to achieve superior results.

Download our Lithium Filtration Brochure today!